Cold Room Panels

Cold storage panels offer excellent thermal insulation, ensuring consistent temperature control for efficient energy use. They are durable, resistant to moisture and corrosion, extending the lifespan of cold storage facilities. Additionally, these panels are easy to install, with customizable sizes and thicknesses to suit various storage needs.

Insulation panels we provide

The following are the types and categories of insulation boards that you can choose from. You can customize the insulation boards according to the diverse processing needs of your processing plant, and we can also recommend them according to your specific needs.

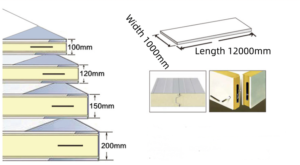

Panel Size

Thickness from 50mm to 200mm, Width 1000mm, and Length 12000mm and even longer.

Steel plate material

Color steel, stainless steel, non-slip aluminum, embossed aluminum etc.

Panel type

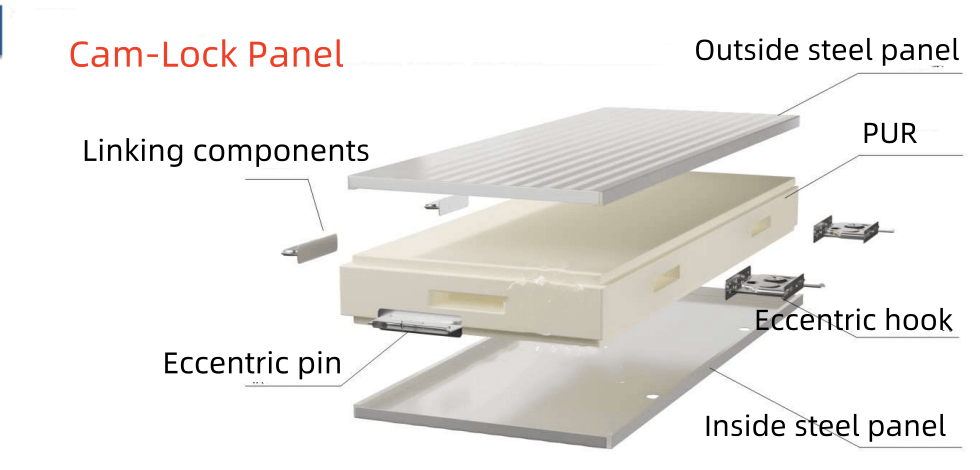

Cam-Lock Panel

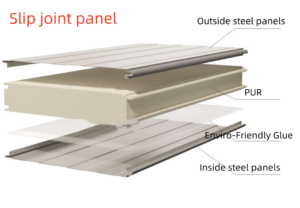

Slip Joint Panel

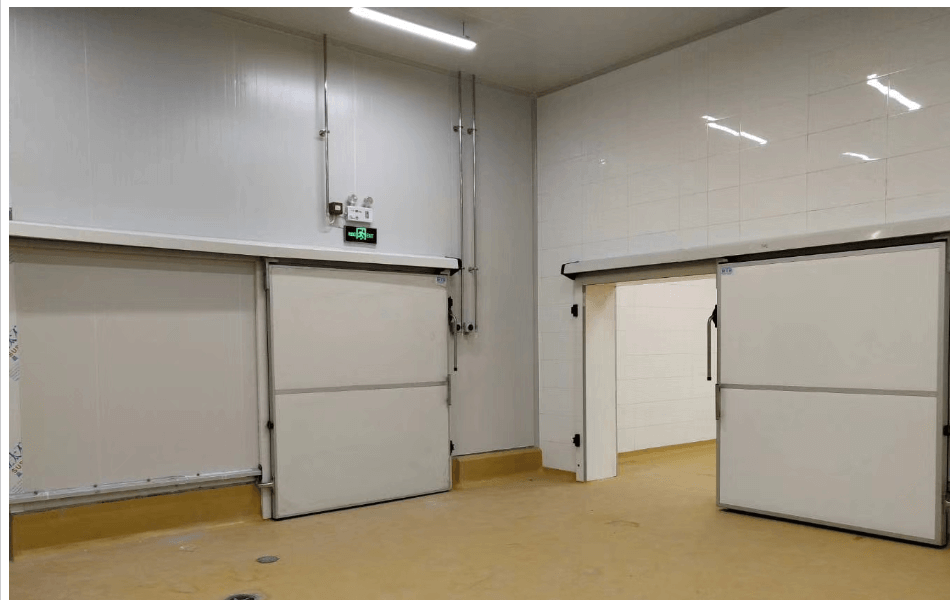

Doors series we provide

The selection of cold storage doors is based on the customer’s cold storage size, the operation mode in the cold storage, etc. The following are the types of cold storage doors we can provide.

Semi Buried Door

Fully Buried Door

Manual Single-Opening Sliding Door

Electric Single-Opening Sliding Door

Double Open Semi Buried Door

Double Open Fully Buried Door

Durable, Fire-Resistant, Eco-Friendly Panels with Superior Insulation and Quick Installation

- Superior Insulation Performance: The polyurethane core offers excellent insulation properties, combined with an innovative interlocking system and well-designed installation joints, ensuring a tight seal and optimal thermal insulation for the entire cold storage enclosure.

- Durable Panels: Made with high-quality pre-painted steel or stainless steel, the panels are strong and resistant to corrosion. With a closed-cell rate of over 90% and a water absorption rate of less than 3%, the panels maintain their performance over time.

- Good Fire Resistance: Polyurethane is a thermosetting resin that forms a charred protective layer during combustion, preventing melting and dripping as seen with EPS and XPS. When combined with metal facings, its fire resistance is further enhanced.

- Strict Environmental Standards: The selection and processing of polyurethane panels strictly adhere to national and industry environmental standards. The panels are resistant to bacteria and parasites, making them suitable for the complex and stringent requirements of the cold chain industry.

- Easy and Fast Installation: Factory-prefabricated panels and a mature installation system make on-site assembly simple and quick, significantly reducing construction time, labor costs, and material waste.

Let's Talk About Your Panels and Doors Requests

Pls tell us What kind of products you want to store inside and what’s the temperature you need and if any other special requests. With those information, we will quickly respond with detailed solutions and quotes. Act Now!

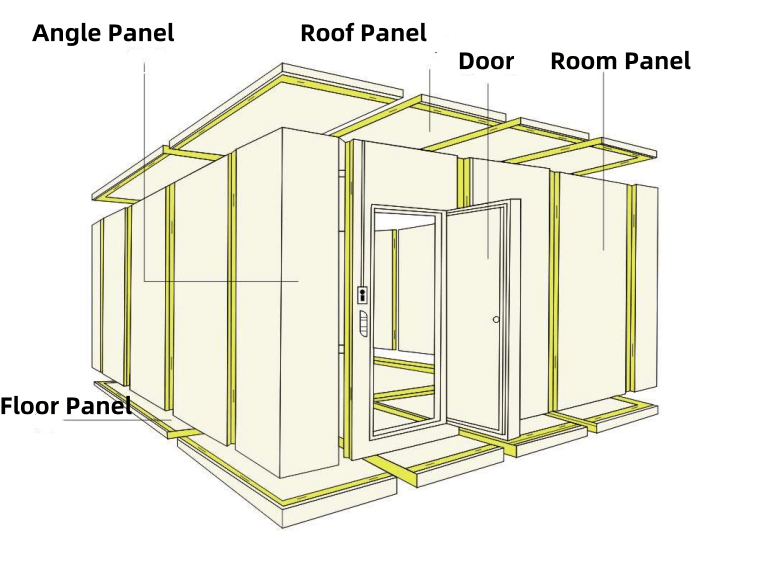

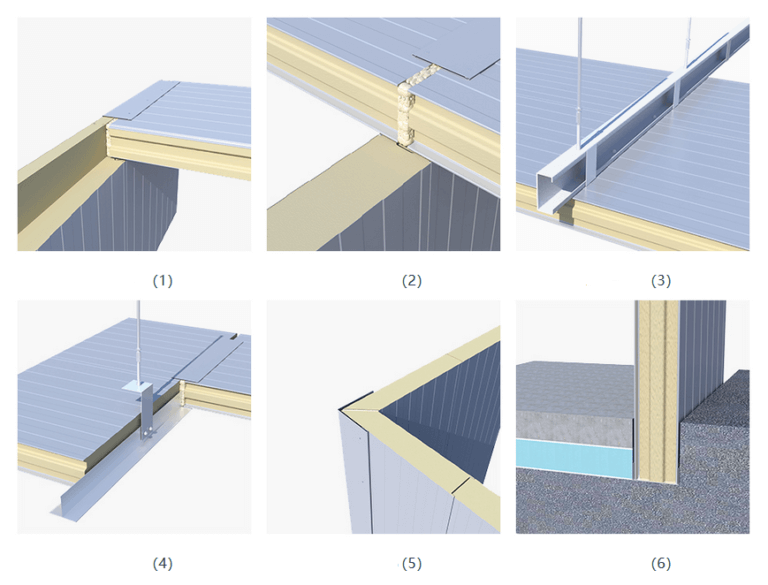

Reference to the diagram for the structural layout of assembling cold storage panels into an insulated room

Cold Storage Panel Installation Details Display

Cam Lock and Slip Joint Panel Parameters

| Number | Item | Unit | Technical Details |

|---|---|---|---|

| 1 | Density | Kg/m³ | 40±2 |

| 2 | Heat Conductivity | W/m.k | ≤0.026 |

| 3 | Compressive Strength | Kpa | ≥150 |

| 4 | Combustion Performance | B2 Grade | |

| 5 | The Bond Strength Between | Mpa | >0.1 |

| 6 | Outside Steel Thickness | Mm | 0.4-0.8 |

| 7 | Outside Steel Coating | HDP/SMP/PE | |

| 8 | Inside Steel Coating | Mm | 0.3-0.6 |

| 9 | Inside Steel Coating | HDP/SMP/PE |

Comparison of Cam-lock and Slip Joint Panel

| Number | Item | Slip-Joint Panel | Cam-Lock Panel |

|---|---|---|---|

| 1 | Production Technology | High-pressure automatic continuous foaming, the entire foaming process is uniform, the thermal conductivity is stable, the density at each point is consistent, the closed cell rate is more than 98%, and the thermal insulation effect is good | Manual extrusion foaming is suitable for non-standard customization, and the size and thickness can be customized according to customer needs. |

| 2 | Flame Retardant Grade | B1 | B2 |

| 3 | Production efficiency | Continuous automatic production, the whole process is controlled by computer system intelligently, with excellent quality and no errors. The daily output of a single line is 12,000 square meters | The manual line is intermittently produced. The steel plates on both sides of the cold storage panel are manually placed into the mold, and a foaming gun is inserted into the mold for foaming. The daily output can reach 3,000 square meters. |

| 4 | Strength | High adhesion between steel plate and core material and high strength | High adhesion between steel plate and core material and high strength |

| 5 | Density | ≥45±2kg kg/m3 | ≥40±2kg kg/m3 |

| 6 | Suggested Room Size | ≥500m³ | ≤ 500m³ |

Flame Retardant Test

The cold storage panel is classified as B1 fire-resistant, with an oxygen index of ≥30, making it a flame-retardant material that cannot sustain combustion even when exposed to continuous fire.