Freezer Room

A freezer room is primarily used for storing items that require long-term freezing, such as meat, seafood, ice cream, frozen foods, biological products, and certain chemical raw materials. In the food industry, a freezer room effectively inhibits microbial growth, delays food spoilage, and preserves the nutritional value and taste of the food. In the pharmaceutical industry, a freezer room provides a stable environment for sensitive biological products such as vaccines and blood products. In the chemical sector, a freezer room is used to store volatile, flammable, or temperature-sensitive raw materials and products.

The freezer room uses a precise temperature control system to maintain the internal temperature within the optimal range required for food freezing. Typically, for most meats and seafood, the ideal temperature range is between -25°C and -18°C. This low-temperature environment significantly slows down the growth and reproduction of microorganisms, thereby delaying the spoilage process of the food.

Fish Freezer

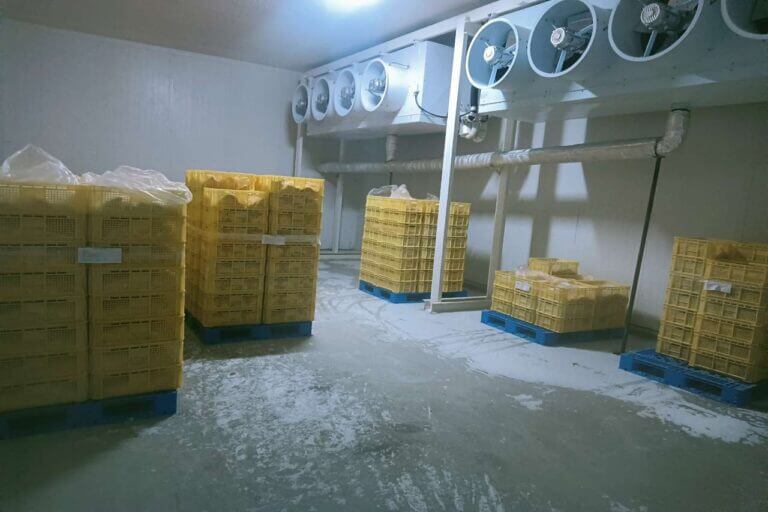

Chicken Freezer

Seafood Freezer

Advantages of Icepoint Freezer Room

Here are the three selling points for freezer rooms, with a length between the original and the condensed versions:

1. Optimal Product Preservation: Freezer rooms maintain consistently low temperatures, essential for preventing spoilage and extending the shelf life of perishable goods such as meat, seafood, and pharmaceuticals. This preservation ensures that products retain their quality, freshness, and nutritional value, resulting in less waste and better product integrity.

2. Energy-Efficient Customization: Modern freezer rooms are designed with high-performance insulation and energy-efficient refrigeration systems. These rooms can be customized to meet specific storage needs, ensuring that energy consumption is minimized while maintaining the required freezing conditions. This tailored approach helps in reducing operational costs without compromising on performance.

3. Regulatory Compliance and Safety: Freezer rooms come equipped with advanced temperature and humidity control systems, along with real-time monitoring and alarms. These features ensure that stored products meet strict regulatory standards, particularly in industries like food processing and pharmaceuticals, helping businesses avoid compliance issues and maintain product safety.

Freezer Room Design Can be Customzied

Freezer room refrigeration units can be tailored to the facility size, with options like piston, or screw units. We offer compressor brands including Bitzer, and Hanbell, with other brands available upon request.

Scroll Compressor

Piston Comperssor

Screw Compressor

The units can be customized as either open-type or closed-type, depending on the specific conditions and requirements of the customer’s site. This flexibility ensures optimal performance and ease of installation. Additionally, the design can be adapted to suit different environmental conditions, providing reliable and efficient operation in various settings.

Open Type Cooling Unit

Closed Type Cooling Unit

The cold storage can also be customized as air-cooled or water-cooled based on customer needs. To facilitate operations and observation of goods, the preservation cold storage is equipped with explosion-proof and waterproof special lighting. Additionally, based on specific needs, the storage may be outfitted with shelves, pallets, fire protection systems, safety alarm systems, and automatic defrosting systems. These auxiliary features further enhance the storage efficiency, safety, and convenience of the cold storage.

Frequently Ask Questions

Commonly stored products include meats, seafood, ice cream, frozen foods, pharmaceuticals, and certain chemical raw materials that require low-temperature environments.

Yes, freezer rooms can be customized with various features such as specific temperature settings, shelving, pallet systems, and even specialized equipment like automatic defrosting systems.

Energy efficiency can be optimized by using high-quality insulation, minimizing door openings, and selecting refrigeration units that are properly sized for the room's requirements.

Proper air circulation is crucial for maintaining uniform temperature throughout the freezer room. Goods should be arranged to avoid blocking the airflow from fans and evaporators.

Yes, freezer rooms are an integral part of cold chain logistics, ensuring that temperature-sensitive products remain frozen throughout storage, transportation, and distribution, preserving their quality and safety.

An automatic defrosting system periodically melts the ice that accumulates on the evaporator coils, preventing ice buildup that can hinder airflow and reduce cooling efficiency.

Freezer rooms typically feature non-slip, easy-to-clean flooring that can withstand cold temperatures and resist damage from moisture and frost.

Condensation can occur, especially near the door, but it is managed through proper insulation, door heaters, and dehumidification systems that keep moisture levels in check.

By maintaining consistent, low temperatures, a freezer room helps in complying with food safety regulations, preventing bacterial growth and ensuring that perishable goods are stored in safe conditions.

Freezer rooms can be equipped with backup generators to ensure continuous operation during power outages, protecting the integrity of stored products.

Let's Talk About Your Freezer Room Requests

Pls tell us which country will you use the machine. What kind of products you want to store and what’s the daily capacity you need. With those information, we will quickly respond with detailed solutions and quotes. Act Now!