MAXIMIZE YOUR BLAST FREEZER ROOM INVESTMENT AND START PROFITING QUICKLY

Blast Freezer Room Manufacturer in China

From +25°C to –40°C in Hours Freeze Fast, Freeze Right

As an expert manufacturer, Icepoint offers high-quality Custom Blast Freezer Room solutions to preserve the freshness of your food products.

The 3 Key Factors to Consider When Purchasing a Blast Freezer Room

1st Freezing Capacity & Speed

A blast freezer room must be capable of handling large volumes while freezing quickly to maintain product quality. Ice Point blast freezer rooms are designed to maximize freezing efficiency, offering rapid cooling even for bulk items, ensuring freshness and texture are perfectly preserved.

2nd Temperature Control & Uniformity

Consistent and accurate temperature control is essential for uniform freezing. Ice Point provides advanced temperature regulation, allowing for precise control across the entire freezer room. This ensures that every product, from the smallest cut to the largest, is frozen evenly and maintains its quality.

3rd Energy Efficiency & Cost:

Key Mechanisms and Benefits of Blast Freezing

Blast freezing holds commercial value by preserving quality and extending shelf life. Rapidly lowering the core temperature to -18°C maintains nutritional value, flavor, and texture. This allows businesses to deliver products with fresh taste and quality, even after storage and transport, adding value for retailers and consumers while reducing waste.

The process quickly passes food through its ice crystal formation zone, creating small ice crystals to prevent cellular damage and keep changes reversible. This ensures safe preservation without compromising quality, making it essential for industries that depend on maintaining product freshness.

Configurations of Blast Freezer Room

| NO | Quick Freezing Capacity (T/4H) | Quick Freezing Capacity (T/6H) | Quick Freezing Capacity (T/8H) | Compressor Refrigeration Capacity(kw) | Compressor Power (kw) | Cooling fan heat exchangeCapacity(kw) | Cooling fan Power (kw) | Water Cooling Tower Fan Power (kw) | Water Cooling Tower Pump Power (kw) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.8 | 1.2 | 1.6 | 24 | 19.1 | 35 | 2.8 | 0.55 | 1.5 |

| 2 | 1.0 | 1.5 | 2 | 34 | 31.7 | 45 | 4.4 | 0.75 | 2.2 |

| 3 | 1.3 | 2.0 | 2.6 | 40 | 37.1 | 52 | 6.6 | 0.75 | 2.2 |

| 4 | 1.6 | 2.4 | 3.2 | 48 | 47.2 | 61 | 8.8 | 1.5 | 4 |

| 5 | 2.0 | 3.0 | 4 | 58 | 52.9 | 75 | 11 | 1.5 | 4 |

| 6 | 3.0 | 4.5 | 6 | 80 | 78.3 | 104 | 13.2 | 1.5 | 5.5 |

| 7 | 3.5 | 5.3 | 7 | 96 | 83.6 | 124 | 17.6 | 1.5 | 5.5 |

| 8 | 4.2 | 6.3 | 8.4 | 118 | 106.9 | 153 | 22 | 2.2 | 5.5 |

The parameters in this table are for reference only and may be updated. Any changes will be reflected in the final design and specific quotation.

Please note that the table is based on the cooling capacity required for quick-freezing fish and may not be applicable to other quick-frozen products. For specific requirements, please contact our sales team for a tailored solution.

The Components, Advantages, and Benefits of Blast Freezer Room.

Outdoor Refrigeration Unit for Freezer Room

Top-brand parts ensure quality and performance.

We offer compressor brands including Bitzer, and Hanbell, the Danish Danfoss expansion valve and the Italian Castel solenoid valve etc to ensure optimal performance of key refrigeration components. With other brands available upon request.

Indoor Air Cooling Fan for Blast Freezer Room

Customizable Air Cooler

Different types of air coolers, such as cylinder type ceiling air coolers and Floor-standing air cooler can be selected and designed according to the specific needs of your blast freezer room.

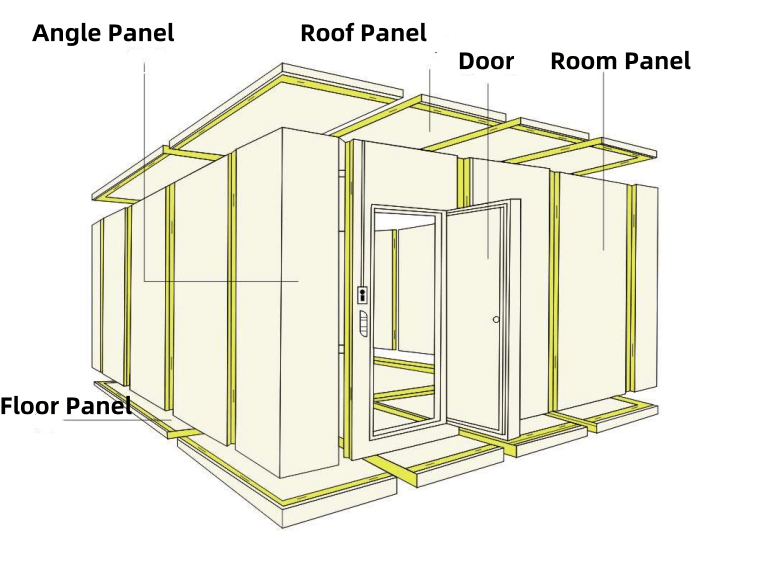

Panels for Blast Freezer Room

Blast Freezer Panels Specifications and Options

Panels thickness

usually adopt 150 or 200 mm thickness.

Width 1000mm, and Length 12000mm and even longer.

Steel plate material

can be Color steel, stainless steel, non-slip aluminum, embossed aluminum etc.

Panel type

can be Cam-Lock Panel or Slip Joint Panel

Application of Blast freezer room

Chicken

Seafood

Meat

Blast freezing technology is extensively used across various industries, including seafood, meat, ready-made meals, bakery goods, dairy products, and even in the pharmaceutical sector for preserving temperature-sensitive items. The versatility and efficiency of blast freezers make them an innovative solution for maintaining product integrity throughout the supply chain, from production to the end consumer.

Customer case of blast freezer room

Chicken Blast Freezer Room

Meat Blast Freezer Room

Fish Blast Freezer Room

Our factory insight

Refrigeration Unit

Production Line

Panels Production Line

Our Service

Pre-Sales Design Service

After-Sales Onsite Service

After-Sales Online Service

Frequently Ask Questions

Commonly stored products include meats, seafood, ice cream, frozen foods, pharmaceuticals, and certain chemical raw materials that require low-temperature environments.

Yes, freezer rooms can be customized with various features such as specific temperature settings, shelving, pallet systems, and even specialized equipment like automatic defrosting systems.

Energy efficiency can be optimized by using high-quality insulation, minimizing door openings, and selecting refrigeration units that are properly sized for the room's requirements.

Proper air circulation is crucial for maintaining uniform temperature throughout the freezer room. Goods should be arranged to avoid blocking the airflow from fans and evaporators.

Yes, freezer rooms are an integral part of cold chain logistics, ensuring that temperature-sensitive products remain frozen throughout storage, transportation, and distribution, preserving their quality and safety.

An automatic defrosting system periodically melts the ice that accumulates on the evaporator coils, preventing ice buildup that can hinder airflow and reduce cooling efficiency.

Freezer rooms typically feature non-slip, easy-to-clean flooring that can withstand cold temperatures and resist damage from moisture and frost.

Condensation can occur, especially near the door, but it is managed through proper insulation, door heaters, and dehumidification systems that keep moisture levels in check.

By maintaining consistent, low temperatures, a freezer room helps in complying with food safety regulations, preventing bacterial growth and ensuring that perishable goods are stored in safe conditions.

Freezer rooms can be equipped with backup generators to ensure continuous operation during power outages, protecting the integrity of stored products.

Let's Talk About Your Blast Freezer Room Requests

Take advantage of our special promotions during the Canton Fair from October 15 to November 4!

Contact us now for pricing details and discover how we can support your refrigeration needs!