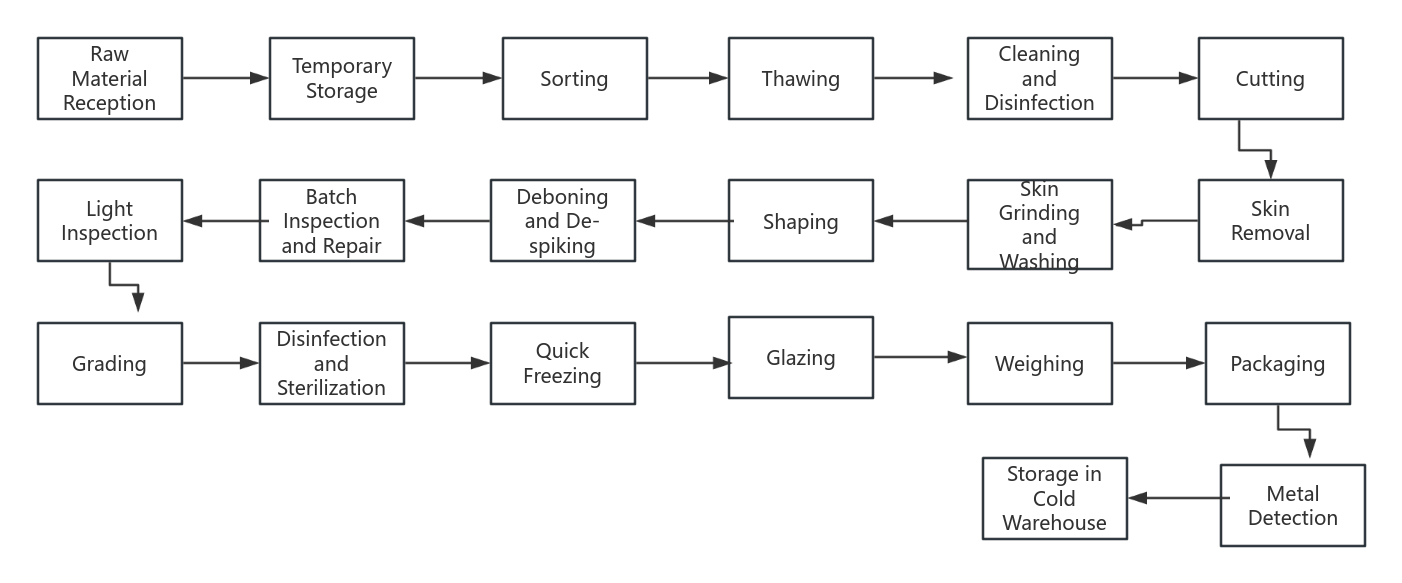

Fish Processing Plant Projects

This is the general processing flow for a typical fish processing plant, based on the procedures followed by our previous clients. If your facility has additional or fewer steps, we can adjust the process according to your specific needs.

The Refrigeration Equipment Needs for the Processing Plant

1. Processing room: 10-15°C

2. Quick Freezing: Tunnel freezer

IQF (Individual Quick Freezing) is used for freezing. When freezing, fish should be evenly and neatly placed on the freezing conveyor belt, avoiding overcrowding or overlapping. Before freezing, the temperature of the freezing tunnel should be lowered to below -35°C. The fillets should then be placed in the tunnel, with the temperature during the freezing process maintained below -35°C. The freezing time should be controlled within 50 minutes, and the final core temperature of the product should be below -18°C.**

3. Glazing: Flake ice or tube ice mixed with water to form chilled water

The water used for glazing should be pre-cooled to below 4°C and prepared as ice water for later use. Frozen fish should be immersed in the ice water or sprayed with it for 3 to 5 seconds, allowing a suitable, even, and transparent layer of ice to form on the surface.

4. Storage room: -18°C

After the product passes inspection, it should be promptly transferred to the cold storage for freezing, with the temperature maintained below -18°C. The temperature fluctuation in the cold storage should be controlled within 3°C. The product must not be stored with toxic, harmful, or odorous items. During loading and unloading, the first-in, first-out (FIFO) principle should be followed.

5. Flake ice machine