Chicken Processing Plant Projects

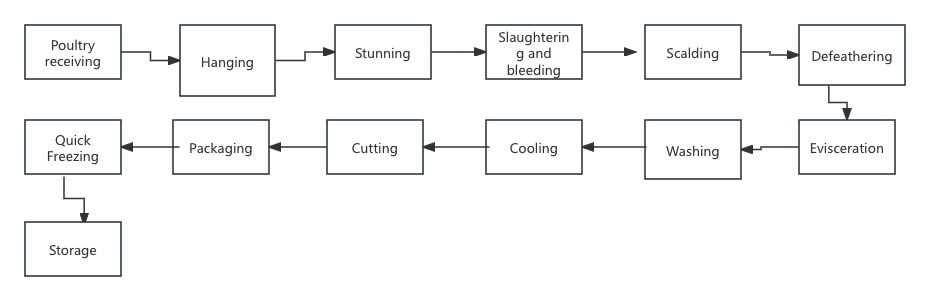

This is the general processing flow for a typical chicken processing plant, based on the procedures followed by our previous clients. If your facility has additional or fewer steps, we can adjust the process according to your specific needs.

The Refrigeration Equipment Needs for the Processing Plant

| Process | Refrigeration Equipment | Purpose | Temperature | Cold Storage Method |

|---|---|---|---|---|

| 1 | Flake Ice Machine | After slaughter, carcasses enter a water tank for cooling. Usually, flake ice is added to the tank to maintain water temperature at 0–4°C. The carcass temperature should be cooled to below 10°C, with a pre-cooling time of about 45 minutes. Fresh water should be added to the tank as needed. | 0–4°C | Chiller Room |

| 2 | Cutting Room | Room for cutting poultry meat, inhibiting bacterial growth | 10–15°C | Double-side air cooler |

| 3 | Cold Storage | Temporary storage of chilled or cut poultry meat for sale | 0–4°C | Chiller Room |

| 4 | Quick Freezing | Quick freezing of cut poultry meat | -35°C | Air-cooled quick freezing/Freezing tunnel, depending on specific needs |

| 5 | Cold Storage | Storing frozen poultry meat | -18°C | Freezer Room |

Need more help?

Contact us right now