MAXIMIZE YOUR CHILLER ROOM INVESTMENT AND START PROFITING QUICKLY

Chiller Room Manufacturer in China

From 10 to 100,000 + Cubic Meters

As an expert manufacturer, Icepoint offers high-quality Custom Chiller Room solutions to preserve the freshness of your products

The 3 Key Factors to Consider When Purchasing a Chiller Room

1st Stable and Reliable Operation

Your cold room must maintain a consistent temperature without breakdowns to ensure product quality. Reliable operation protects the high value of stored goods, often more valuable than the cold room itself. Stability is key to preserving product quality and profits.

2nd Cost-Effective and Energy-Efficient Solutions

Our equipment offers affordable pricing with reliable quality. Designed for energy efficiency and tailored to your usage needs, our systems help reduce operational costs, ensuring quicker return on your investment.

Customized Cold Room Design with Full Support

The Components, Advantages, and Benefits of our Chiller Room.

Outdoor Refrigeration Unit for Chiller Room

Top-brand parts ensure quality and performance.

We offer compressor brands including Bitzer, and Hanbell, the Danish Danfoss expansion valve and the Italian Castel solenoid valve etc to ensure optimal performance of key refrigeration components. With other brands available upon request.

Customized closed-type design

The flexibility ensures optimal performance and ease of installation. Additionally, the design can be adapted to suit different environmental conditions, providing reliable and efficient operation in various settings.

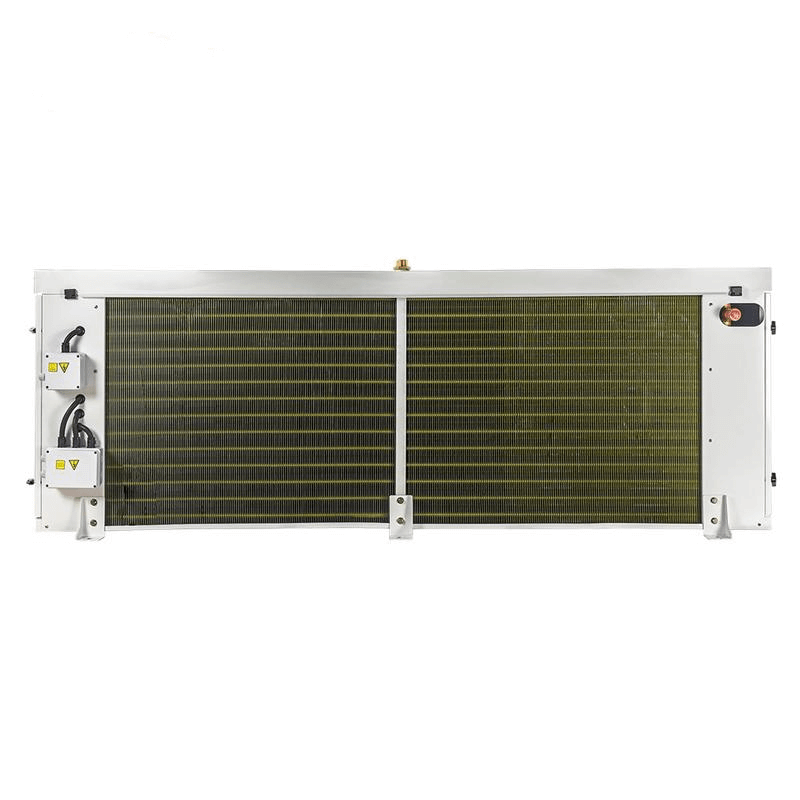

Indoor Air Cooling Fan for Chiller Room

Key Features of Freezer Air Cooler Design

External Casing

High-quality steel with anti-corrosion coating. Hinged plates and tray for easy use.

Fan

Powerful external rotor fan with high wind volume, long airflow, low noise, and independent wiring box.

Defrosting

Standard electric heating defrost; options for hot gas or combined defrost solutions available.

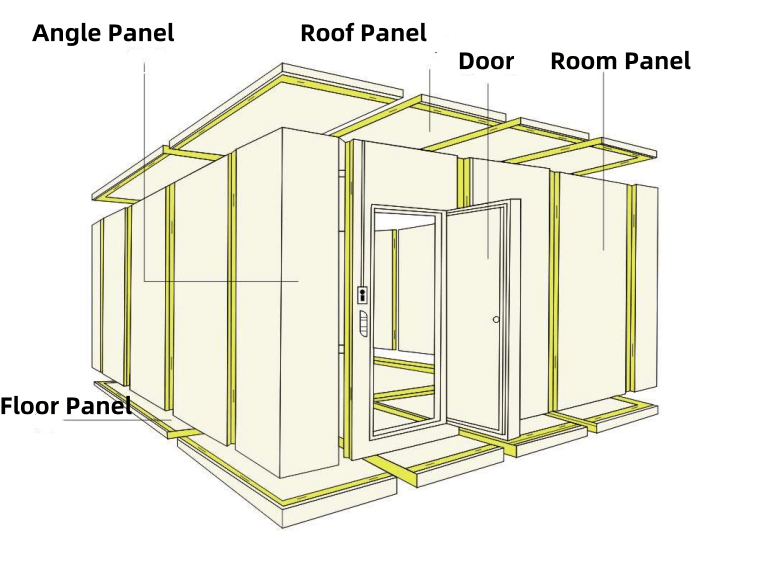

Panels for Chiller Room

Chiller Panels Specifications and Options

Panels thickness

can adopt 75mm, 100 mm thickness.

Width 1000mm

Steel plate material

can be Color steel, stainless steel, non-slip aluminum, embossed aluminum etc.

Panel type

can be Cam-Lock Panel or Slip Joint Panel

Key Advantages of Polyurethane Chiller Room Panels

Superior Insulation:

Polyurethane core and interlocking joints provide a tight seal for optimal thermal insulation.

Durable Panels:

High-quality steel, corrosion-resistant, over 90% closed-cell rate, low water absorption.

Fire Resistance:

Polyurethane creates a protective charred layer, improving fire resistance with metal facings.

Application of Chiller room

Fruits Chiller

Vegetables Chiller

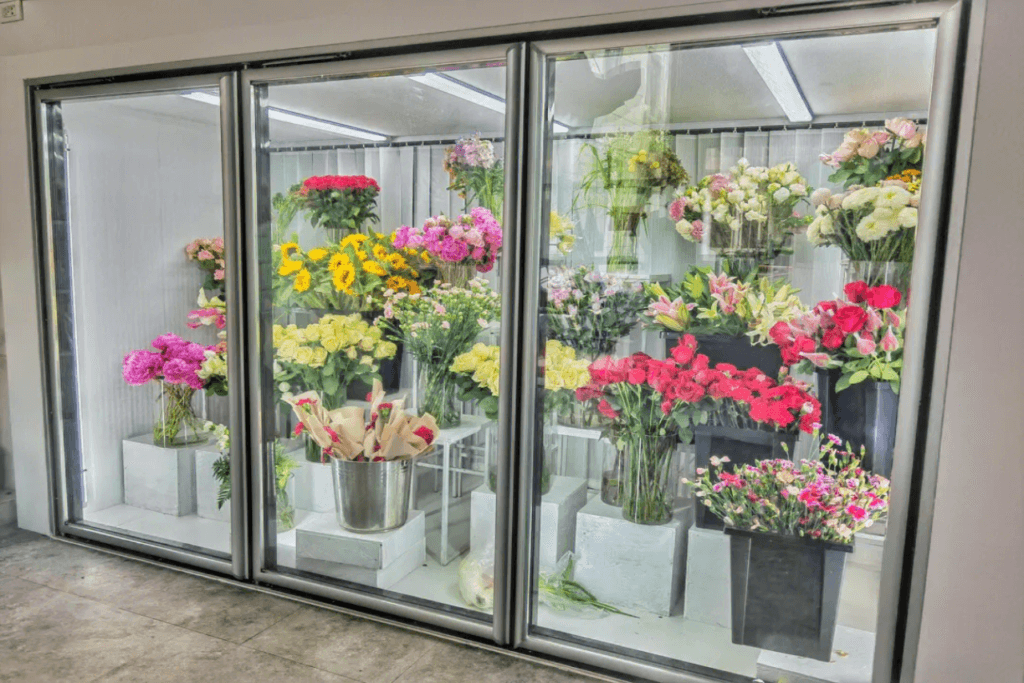

Flowers Chiller

Preservation cold storage extends product shelf life by using low temperatures to suppress microbial and enzymatic activity. It is essential for industries like food and floriculture, providing storage for fresh products such as fruits, vegetables, and flowers to maintain quality and reduce spoilage. This controlled environment ensures products remain fresh during transportation and sales.

Customer case of Chiller room

Fruits Chiller

Vegetables Chiller

Flowers Chiller

Our factory insight

Refrigeration unit

Production Line

Panels Production Line

Our Service

Pre-Sales Design Service

After-Sales Onsite Service

After-Sales Online Service

Frequently Ask Questions

High-temperature cold storage usually operates within a temperature range of 0°C to 15°C, depending on the specific requirements of the stored goods.

The choice of refrigeration unit, such as scroll, piston, or screw types, depends on the size of the storage facility and the specific cooling requirements.

Yes, units can be tailored to match the specific conditions of the installation site, including options for open-type or closed-type systems.

Regular maintenance is necessary, including checking and servicing the refrigeration system, cleaning the condenser, and ensuring proper insulation to maintain efficiency.

High-temperature cold storage slows down the ripening process without halting it entirely, which is ideal for extending the shelf life of certain produce without compromising quality.

High-temperature cold storage typically uses insulation materials like polyurethane panels, which provide excellent thermal resistance to maintain a stable internal temperature.

Yes, high-temperature cold storage can be equipped with advanced monitoring systems that track temperature, humidity, and gas levels in real-time, providing alerts for any deviations from set parameters.

Safety features can include fire suppression systems, explosion-proof lighting, emergency alarms, and backup power systems to ensure the safety of the stored products and the facility.

To enhance energy efficiency, it's essential to minimize the frequency of opening the cold storage door during daily operations, as frequent openings allow warm air to enter, increasing the cooling load. Additionally, using high-quality insulation materials for the cold storage panels and doors, and ensuring that the refrigeration units are appropriately sized and matched to the storage needs, can significantly reduce energy consumption.

To ensure efficient air circulation, it's crucial to arrange the stored goods in a way that doesn't block the air flow. Specifically, avoid placing items in front of the evaporator fan's intake or exhaust areas. Providing adequate space around the stored products allows for sufficient air movement, which is vital for maintaining uniform temperature and humidity levels throughout the storage unit.

Let's Talk About Your Chiller Room Requests

Take advantage of our special promotions during the Canton Fair from October 15 to November 4!

Contact us now for pricing details and discover how we can support your refrigeration needs!