Flake Ice Machine with Ice Storage

Choose us as your flake ice machine supplier for reliable, high-efficiency solutions that ensure your products stay fresh and undamaged. Our machines are designed to deliver consistent, quality ice tailored to meet the unique needs of your industry.

The Products IcePoint Offer You

IcePoint has many years of design and production experience and accepts non-standard customization of different ice-making equipment. Customers can choose the ice-making equipment that suits them based on the material, refrigeration accessories, and condensation method of the ice-making equipment.

We can provide flake ice machines with daily output ranging from 1 ton to 30 tons per unit

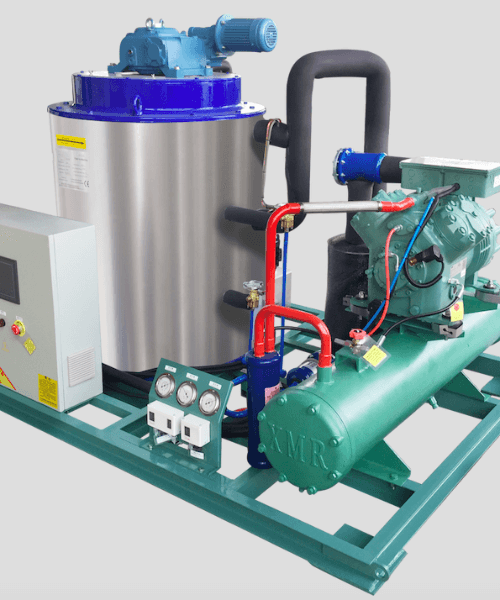

1 Tons Flake Ice Machine

3 Tons Flake Ice Machine

5 Tons Flake Ice Machine

10 Tons Flake Ice Machine

20 Tons Flake Ice Machine

30 Tons Flake Ice Machine

Flake Ice Machines with High Precision, Reliability, and Efficiency

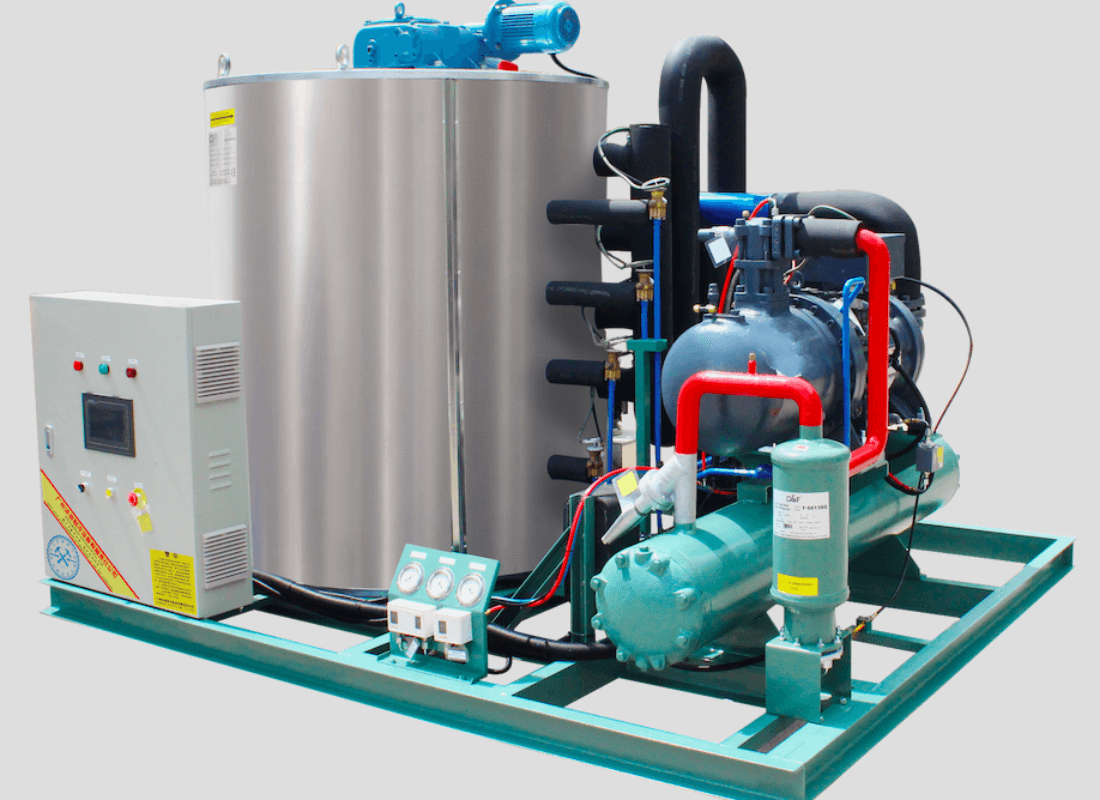

Our flake ice machine features a streamlined and efficient refrigeration system. We meticulously control every step of the manufacturing process, from selecting premium raw materials and using advanced processing equipment to implementing precise craftsmanship and rigorous quality inspections, ensuring the highest level of durability and quality. Our equipment stands out with the following key advantages.

- In-house Design and Manufacturing: Flake ice evaporator is designed and manufactured according to pressure vessel standards, ensuring durability and zero leakage. The machine produces ice continuously at low temperatures, ensuring both the low temperature of the ice flakes and high ice-making efficiency.

- Top-tier Refrigeration Components: We use globally recognized brands for refrigeration components, such as compressors from Bitzer (Germany), Danfoss (Denmark), Copeland (USA), Hanbell (Taiwan), and Refcomp (Italy), ensuring the equipment’s high quality, low failure rate, and industry-leading ice-making efficiency.

- Fully Automated Intelligent Control: The machine is equipped with a fully automated control system, enabling unattended operation. It can intelligently detect and respond to issues such as phase loss, overload, water shortage, full ice storage, and low or high pressure, ensuring stable operation.

- International Certification: The complete machine is certified by CE and SGS, guaranteeing that the equipment meets international safety and quality standards.

Fake ice machine delivers exceptional ice-making efficiency and reliable performance, making it the ideal solution to boost your production efficiency with durable, low-maintenance equipment.

Let's Talk About Your Ice Machine Requests

Pls tell us which country will you use the ice machine. What kind of products you want to cool and what’s the daily capacity you need. Do you need an ice storage to preserve the ice before usage. With those information, we will quickly respond with detailed solutions and quotes. Act Now!

Flake Ice Features

The characteristics of flake ice are as follows:

- Shape and Size: Flake ice is typically thin and flat, with a thickness of about 1.5-2.2 mm. It has a large surface area but is light and easy to stack and spread.

- Low Temperature: Flake ice has a low temperature, usually ranging from -5°C to -8°C, which allows it to quickly cool items and maintain their freshness.

- Excellent Contact: Due to its shape and large surface area, flake ice can make close contact with the objects it cools, enhancing cooling efficiency.

- Softness: Flake ice is relatively soft, which prevents it from damaging the surface of the items it cools, making it ideal for preserving delicate products like seafood, fruits, and vegetables.

- Slow Melting: Flake ice has a lower density and melts more slowly, providing extended cooling effects.

- Low Production Cost: The energy consumption for producing flake ice is low, making it cost-effective and suitable for large-scale industrial cooling applications.

Flake Ice Application

Flake ice is widely used in aquatic product preservation, food processing, meat processing, fresh food supermarkets, fishery production, cold chain logistics, medical research, chemical printing and dyeing, concrete cooling and other industries.

Seafood Process and Preservation

Flake ice can reduce the temperature of processing media, washing water, and aquatic products, prevent bacterial growth, and keep aquatic products fresh during processing.

Meat Process and Preservation

Add flake ice that meets hygiene standards to meat and stir. To achieve the purpose of cooling and preservation.

Food process and preservation

Flake ice to quickly cool down when stirring or creaming bread to prevent fermentation.

Cold Chain Transportation

Cold chain logistics, deep-sea fishing, vegetable transportation, and other products that need cooling and preservation are increasingly widely used for cooling and preservation in long-distance transportation.

Chemical and Medicine

It is also widely used in chemical printing and dyeing, medicine, scientific laboratories and other industries.

Concrete mixing

When concrete is poured on a large scale in hot seasons, ice flakes are used to control the pouring and transportation temperature of concrete.

Flake Ice Machine Features

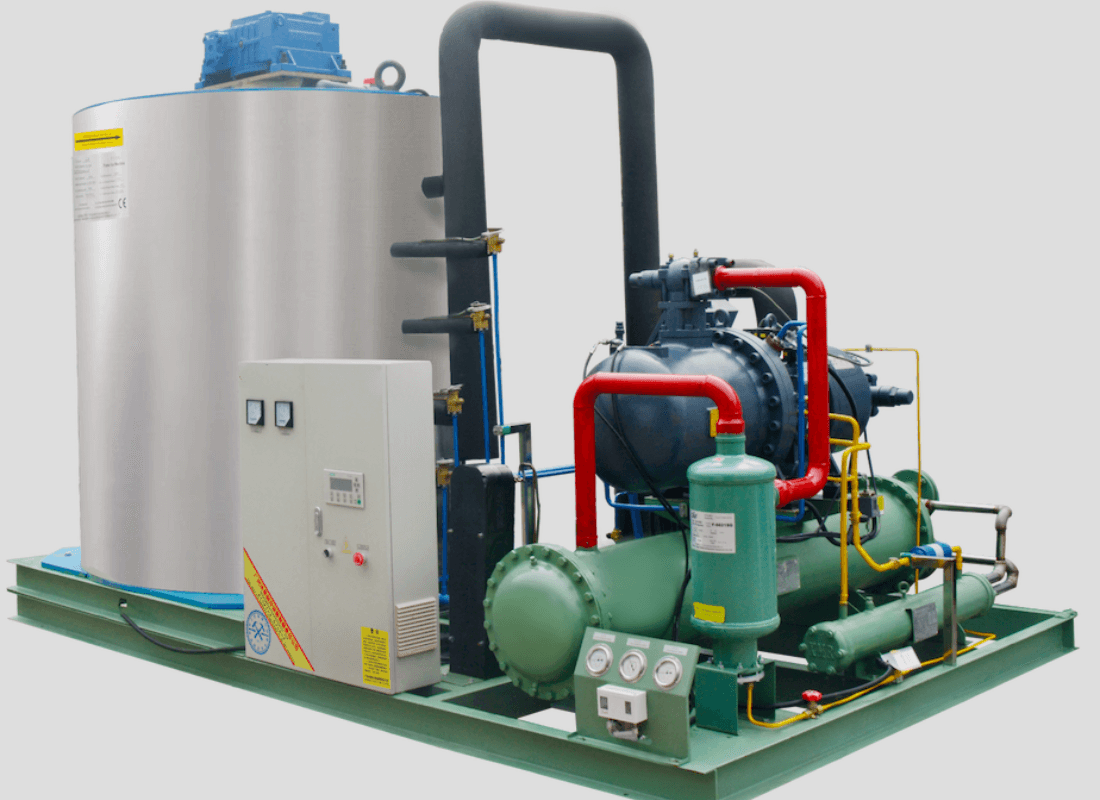

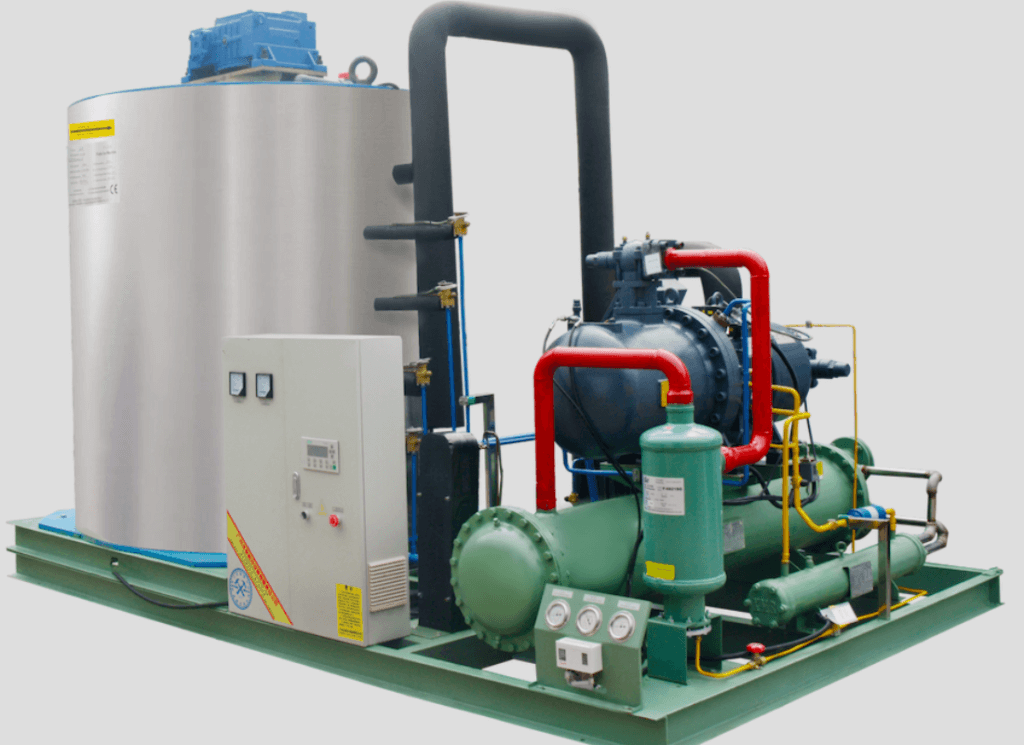

Efficient Refrigeration System: The flake ice machine features a streamlined yet highly efficient refrigeration system, enabling rapid ice production while maintaining low-temperature properties.

Continuous Ice Production: The machine is capable of continuous ice production, providing a consistent supply of high-quality flake ice to meet large-scale production needs.

Fully Automated Control System: Equipped with a fully automated control system, the machine can operate unattended, intelligently managing issues like phase loss, overload, and water shortages to ensure stable operation.

High Durability: Built with premium materials and subjected to rigorous quality inspections, the flake ice machine is designed for long-lasting durability and reliable performance.

Easy Maintenance: The machine’s design facilitates easy maintenance and repairs, reducing downtime and enhancing production efficiency.

International Certification: The flake ice machine is certified by CE and SGS, ensuring compliance with global safety and quality standards for reliable and safe operation.

Energy Efficient: The machine is energy-efficient, with low operating costs, making it suitable for long-term, large-scale use.

Technical Parameters

| Model | Daily Output (T/24 h) | Cooling Way | Compressor Power (KW) | Fan Power for Cooling tower (KW) | Cooling Pump Power (KW) | Unit size (L*W*Hmm) | Unit N.W.(kg) |

|---|---|---|---|---|---|---|---|

| IPF1000 | 1 | Air | 7.44 | - | 1320*900*900 | 210 | |

| IPF2000 | 2 | Air | 10 | - | 1750*1100*900 | 360 | |

| IPF3000 | 3 | Air | 8.45 | - | 1.5 | 1500*1250*1260 | 1000 |

| IPF5000 | 5 | Water | 13.49 | 0.75 | 2.2 | 1900*1500*1470 | 1100 |

| IPF8000 | 8 | Water | 24.2 | 1.5 | 2.2 | 2400*1900*1860 | 1300 |

| IPF10000 | 10 | Water | 33.8 | 1.5 | 4 | 2500*2000*1860 | 1500 |

| IPF15000 | 15 | Water | 44.5 | 1.5 | 4 | 3350*2150*1960 | 3200 |

| IPF20000 | 20 | Water & Evaporative | 64 | 1.5 | 5.5 | 3400*2220*2230 | 4200 |

| IPF25000 | 25 | Water & Evaporative | 76.5 | 2.2 | 5.5 | 3700*2250*2510 | 4600 |

| IPF30000 | 30 | Water & Evaporative | 93.7 | 2.2 | 7.5 | 4700*2250*2520 | 5000 |

| IPF40000 | 40 | Water & Evaporative | 118 | 2.2 | 7.5 | 5000*2300*2700 | 7500 |

♦Compressor Brand: Bitzer / Hanbell; Refrigerant: R404A or R507;

♦ Power Supply: Voltage 380V/3P/50Hz (For non-standard voltage, unit configuration needs to be calculated separately).

♦ Operating Conditions: T(water supply) : 20 ° C, T(ambient) : 32 ° C, T(condensing) : 38 ° C,T(evaporating):-20℃.

♦ (Note: The actual ice production varies due to the influence of water supply temperature and ambient temperature.)

♦ (The final interpretation of the above metioned parameters is in Icepoint, there will be no further notice, if there is any technical change.)

Flake Ice Machine Operation

The Flake ice will drop and stored inside the cold room after production. The worker use the shovel to carry the ice to the water box to cool the seafood.

Flake Ice Machine Installation Brief Introduction

The installation of a flake ice machine is the simplest among all ice machines. Conventional tonnage only needs to be connected to water and electricity. Therefore, a brief introduction is given here to give you a preliminary understanding of how to install a flake ice machine. For more details, please contact us directly for more detailed information.

Choose an Appropriate Installation Location: The flake ice machine should be installed in a well-ventilated area on a flat and sturdy surface, away from direct sunlight and high-temperature environments to ensure optimal performance.

Ensure Stable Power Supply: Make sure the power supply at the installation site meets the machine’s requirements, and that there is a reliable grounding line to prevent damage from voltage fluctuations.

Water Supply Connection: The machine requires a stable and clean water supply. During installation, ensure that the water inlet pipes are securely connected to avoid leaks. It is also recommended to install a water filter to prevent poor water quality from affecting the ice-making process.

Set Up a Drainage System: The flake ice machine produces wastewater during operation, so a proper drainage system should be in place to ensure smooth drainage and prevent water accumulation that could affect the equipment and surrounding environment.

Initial Testing and Operation: After installation, perform a comprehensive test run, including checking the operation of all components, verifying that the ice production efficiency and quality meet standards, and ensuring the equipment is functioning correctly before full-scale use.

Flake Ice Machine Maintainence Brief Introduction

The regular maintainence is simple and can keep the machine continous running to make profits for you. Here give you a general idea about it. A non refrigeration professional engineer can do it easily.

Regular Cleaning: Clean the interior and exterior of the flake ice machine regularly, including the evaporator, ice storage bin, and water inlet pipes, to prevent dirt and scale buildup that could affect performance.

Inspect the Refrigeration System: Regularly check the refrigerant levels and the operation of the compressor to ensure the refrigeration system is functioning properly, preventing reduced ice-making efficiency due to insufficient refrigerant or compressor issues.

Replace Wearable Parts: Based on usage frequency, periodically replace components like water filters and seals to ensure the continued stable operation of the equipment.

Electrical System Maintenance: Regularly inspect the electrical system, ensuring that all wiring connections are secure and undamaged, and that the control panel is functioning correctly to avoid downtime due to electrical issues.

Operation Records: Keep a record of the machine’s operational parameters and any faults encountered. This helps identify potential issues early, allowing for preventive maintenance and extending the equipment’s lifespan.

Seasonal Checks: Perform special inspections during seasonal changes, especially in warmer weather, to ensure the machine operates reliably under varying environmental conditions.

Frequently Ask Questions

A 5-ton ice machine uses 5 tons of water to produce 5 tons of ice. The water circulates continuously, and the cooling system uses an open water cooling tower, with hourly water consumption below 1% of the tower’s circulating volume.

The standard voltage is 380V/3P/50Hz, and it can be customized to 220V/3P/60Hz, 380V/3P/60Hz, 440V/3P/60Hz, etc., depending on your requirements.

With proper use and regular maintenance, this flake ice machine has an expected lifespan of over 15 years, making it a reliable investment.

Yes, we offer add-ons like water filtration systems and ice storage bins, which can be customized according to your requirements.

The equipment includes a 1-year warranty, starting 15 months or 12 months after installation, whichever comes first. Non-human damage to parts is covered; on-site service is charged, but lifetime online support is free.

The machine is designed to be automatic operation, with straightforward controls and usually worker only need to press the start and stop button to start and stop the machine.

Yes, the machine is compliant with food safety standards and can be used for food processing industries like meat, chicken, seafood, pizza, bread, vegetables, and fruits.

The operating power varies depending on the machine's capacity. It is designed to be energy-efficient, with an average consumption of 70 kWh per ton of ice, ensuring both performance and cost-effectiveness.

We can provide references or arrange for you to contact current users in your area. If this is not possible, we invite you to visit our facilities in China to view our equipment and customer cases.

Contact us Now!