MAXIMIZE YOUR FREEZER ROOM INVESTMENT AND START PROFITING QUICKLY

Freezer Room Manufacturer in China

From 10 to 100,000 + Cubic Meters

As an expert manufacturer, Icepoint offers high-quality Custom Freezer Room solutions to preserve the freshness of your products

The 3 Key Factors to Consider When Purchasing a Freezer Room

1st Stable and Reliable Operation

Your cold room must maintain a consistent temperature without breakdowns to ensure product quality. Reliable operation protects the high value of stored goods, often more valuable than the cold room itself. Stability is key to preserving product quality and profits.

2nd Cost-Effective and Energy-Efficient Solutions

Our equipment offers affordable pricing with reliable quality. Designed for energy efficiency and tailored to your usage needs, our systems help reduce operational costs, ensuring quicker return on your investment.

Customized Cold Room Design with Full Support

The Components, Advantages, and Benefits of our Freezer Room.

Outdoor Refrigeration Unit for Freezer Room

Top-brand parts ensure quality and performance.

We offer compressor brands including Bitzer, and Hanbell, the Danish Danfoss expansion valve and the Italian Castel solenoid valve etc to ensure optimal performance of key refrigeration components. With other brands available upon request.

Customized closed-type design

The flexibility ensures optimal performance and ease of installation. Additionally, the design can be adapted to suit different environmental conditions, providing reliable and efficient operation in various settings.

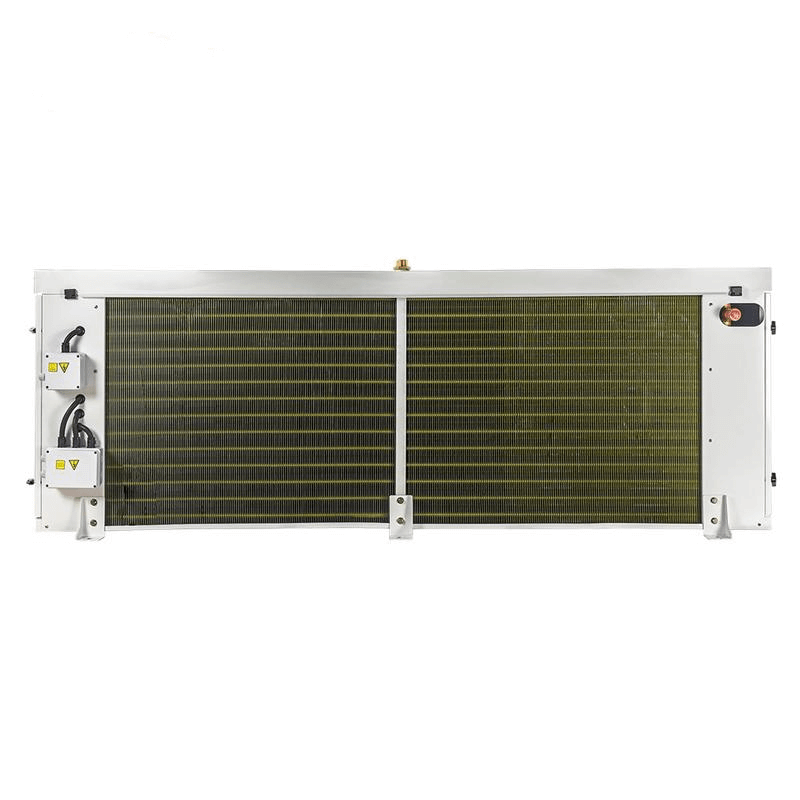

Indoor Air Cooling Fan for Freezer Room

Customizable Air Cooler Options for Cold Storage

Different types of air coolers, such as cylinder type ceiling air coolers, standard ceiling air coolers, and double-sided side air coolers, can be selected and designed according to the specific needs of your cold storage.

Key Features of Freezer Air Cooler Design

External Casing

High-quality steel with anti-corrosion coating. Hinged plates and tray for easy use.

Fan

Powerful external rotor fan with high wind volume, long airflow, low noise, and independent wiring box.

Defrosting

Standard electric heating defrost; options for hot gas or combined defrost solutions available.

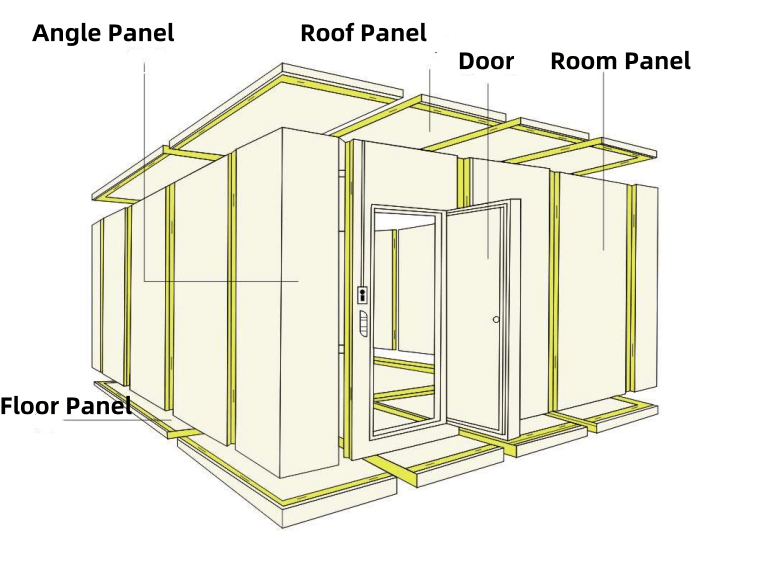

Panels for Freezer Room

Freezer Panels Specifications and Options

Panels thickness

usually adopt 150 mm thickness.

Width 1000mm, and Length 12000mm and even longer.

Steel plate material

can be Color steel, stainless steel, non-slip aluminum, embossed aluminum etc.

Panel type

can be Cam-Lock Panel or Slip Joint Panel

Key Advantages of Polyurethane Freezer Room Panels

Superior Insulation:

Polyurethane core and interlocking joints provide a tight seal for optimal thermal insulation.

Durable Panels:

High-quality steel, corrosion-resistant, over 90% closed-cell rate, low water absorption.

Fire Resistance:

Polyurethane creates a protective charred layer, improving fire resistance with metal facings.

Application of freezer room

Fish Freezer

Chicken Freezer

Seafood Freezer

Meat Freezer

The freezer room is used for long-term storage of items like meat, seafood, ice cream, frozen foods, and certain chemical or biological products.

It preserves quality by slowing microbial growth and spoilage, with temperatures typically between -25°C and -18°C.

Customer case of freezer room

Fish Freezer

Chicken Freezer

Seafood Freezer

Meat Freezer

Our factory insight

Refrigeration Unit

Production Line

Panels Production Line

Our Service

Pre-Sales Design Service

After-Sales Onsite Service

After-Sales Online Service

Frequently Ask Questions

Commonly stored products include meats, seafood, ice cream, frozen foods, pharmaceuticals, and certain chemical raw materials that require low-temperature environments.

Yes, freezer rooms can be customized with various features such as specific temperature settings, shelving, pallet systems, and even specialized equipment like automatic defrosting systems.

Energy efficiency can be optimized by using high-quality insulation, minimizing door openings, and selecting refrigeration units that are properly sized for the room's requirements.

Proper air circulation is crucial for maintaining uniform temperature throughout the freezer room. Goods should be arranged to avoid blocking the airflow from fans and evaporators.

Yes, freezer rooms are an integral part of cold chain logistics, ensuring that temperature-sensitive products remain frozen throughout storage, transportation, and distribution, preserving their quality and safety.

An automatic defrosting system periodically melts the ice that accumulates on the evaporator coils, preventing ice buildup that can hinder airflow and reduce cooling efficiency.

Freezer rooms typically feature non-slip, easy-to-clean flooring that can withstand cold temperatures and resist damage from moisture and frost.

Condensation can occur, especially near the door, but it is managed through proper insulation, door heaters, and dehumidification systems that keep moisture levels in check.

By maintaining consistent, low temperatures, a freezer room helps in complying with food safety regulations, preventing bacterial growth and ensuring that perishable goods are stored in safe conditions.

Freezer rooms can be equipped with backup generators to ensure continuous operation during power outages, protecting the integrity of stored products.

Let's Talk About Your Freezer Room Requests

Contact us now for pricing details and discover how we can support your refrigeration needs!