Pork Processing Plant Projects

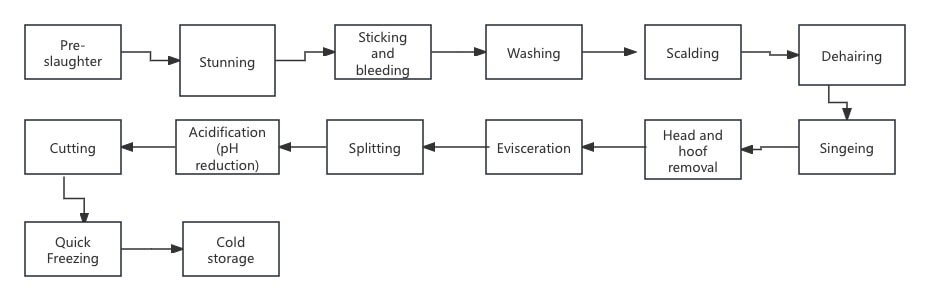

This is the general processing flow for a typical pork processing plant, based on the procedures followed by our previous clients. If your facility has additional or fewer steps, we can adjust the process according to your specific needs.

The Refrigeration Equipment Needs for the Processing Plant

| Process | Refrigeration Equipment | Purpose | Temperature | Cold Storage Method |

|---|---|---|---|---|

| 1 | Semi-finished Product Storage | Storing offal, pig heads, pig feet, etc., inhibiting bacterial growth | 0–4°C | Chiller Room |

| 2 | Acid Removal Storage (24 hours) | Gradual breakdown of lactic acid in the meat, converting it into water and carbon dioxide, thus reducing the lactic acid content in the meat. This prevents the meat from becoming hard and difficult to cook due to lactic acid accumulation. Additionally, the acid removal process aids in enzymatic reactions, breaking down some proteins into amino acids, enhancing the freshness and nutritional value of the meat. | 0–4°C | Chiller Room |

| 3 | Cutting Room | Room for cutting pork, inhibiting bacterial growth | 10–15°C | Double-side Chiller Room |

| 4 | Quick Freezing | Quick freezing of cut pork | -35°C | Air-Cooled quick freezing |

| 5 | Cold Storage | Storing frozen pork | -18°C | Freezer Room |

Need more help?

Contact us right now